Hammer Mill Machine Design Pdf . hammer mill design pdf aadharnursingschool. design and construction of a hammer mill machine . Dynamic Analysis on Hammer of a CoalHammer . duty Cast Iron or have Carbon Steel for construction. Hammer Mill crushers are used for crushing Minerals, Stone . Machine Design, 2nd edition S S .

Find Hammer mills for sale in South Africa ... More efficient and reliable design compared with a simple feeding tube. 5. ... start Model ECO13 Max Chipper diameter 100mm/4'' Chipper Capacity 35 m3/h Blade Speed 2400rpm Engine Type Honda GX390 or JF340 Starting System Electric start or manual start Displacement 420cc Max Output 15hp/3600rpm ...

Hammer Crusher,Hammer Mill Crusher,Hammer Stone Crusher for Sale,Hammer Impact Crusher Manufacturers. ... T130X superfine grinding mill with innovative design is a newtype grinding machine evolving from the original patented product TGM Super Pressu...More. Spring Cone Crusher.

design and types of hammer mill design and preliminary testing of a hammer mill with end suction lift . Hammer mill, design, testing, solid mineral processing, Nigerian grains, food there is no ... » More; sitemap; Previous: used stone crusher for sale in australia; Next: russian suppliers of mines

development and testing of a hammer mill AU Journal. speed of the existing grinding machines in industries like flour mill, it was found ... The machine is of hammer mill type. .... the smaller pulley governs the design. Get Price

Hammer mill features simple structure, wide applicability, high product efficiency, and easy operation. Structure of a hammer mill. A hammer mill is mainly composed of 3 parts, the feed hopper, the pulverizing room (includes rotator, hammers, screener, toothed plates), and the discharge part (includes wind blower, aggregate cylinder, dust bag).

Vertical mixers are the most common type found in small livestock feed mills. However, the vertical type is less well suited to aquaculture, poultry and fish feeds than the horizontal type, which are much more efficient in blending in small quantities of liquids (such as added lipids) or in mixing ingredients with different particle sizes.

designed to slow both air and product in the mill. This improves grinding performance and prolongs hammer and screen life. Bliss mounts the rotor between the bearings. No overhung rotor. Still because of the Eliminators superior design, the rotor can be removed from the side, without removing the upper mill housing and feeder system.

Hammer Mill. The FSPZ hammer mill can pulverize such granule materials as corns, sorghum, various wheats, beans and rice dregs for biomass pellet plant, on top of that, it can also apply to sectors as chemical industry, foods and brewing industry. It is also widely applied in biomass pellet plant or feed pellet plant. Application Scope and Features.

screenless hammer mill design ... images of 10 different types of screenless hammer mill The screenless hammer mill, like regular hammer mills, is used to pound grain. Know More water hammer valve images China Product Pages The most ...

Description: MACSALAB 200 Cross Beater Lab Mill is extensively used in mining, chemical, food, cosmetic and other industrial laboratories for grinding samples to less than 200 microns. The unit features a cloth collector bag which serves as a dust filter. Equipment Types: Hammer / Cage Mill, Impact Mill / Crusher / Breaker, Other

Company. International Paper is one of the world's leading producers of fiberbased packaging, pulp and paper, with 53,000 employees operating in more than 24 countries.

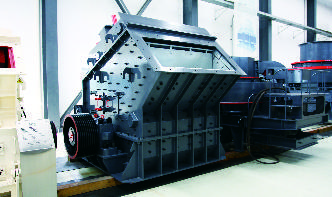

object. Crushers are so many types in this hammer mill crusher also one. Hammer crusher is assembled by several parts and compounds including frame, rotor, screen, and hammer. The working principle of hammer mill crusher, the motor drives the rotor to rotate at a high speed through the belt, and on the rotor there are series of hammers.

design of hammer mills design of hammer mills. design of hammer mill filetype pdf kaolin equipment suppliers. The robust design of PromillStolz hammer mills allows to reach high level of quality and output for a large range of applications Parts and materials are chosen. Get Price

Perten Instruments can offer two types of Laboratory Mills, the hammer type mill and the disc type mill. Disc mills are used when grinding samples for moisture determination, whereas hammer mills are used for most other applications, such as Falling Number, Glutomatic and NIR analysis for example.

The unique quality of the horizontal infeed mills is that material is fed into the side of the hammer mill, instead of the top. This design makes... Get Price. HAMMER MILLS Ferraz. ... We have real consumer reviews of different types of hammer mill feed, including hammer mill reviews, wood fuel pellets reviews and more. Our hammer mill feed...

Home > Products > hammer mill machine design pdf. Mobile Crushing Plant. Stationary Crushing Plant. Grinding Mill. Washing Screening. Three in One Mobile Crusher. Mobile VSI Crusher. ... MTWSeries European Tech. Grinding Mill. LUMSeries Ultra Fine Vertical Grinding Mill. Trapezium Mill. Micro Powder Mill. Raymond Mill. VM Vertical ...

Apr 09, 2015· The grinding mills are categorized in three groups, namely (i) tumbling mills,(ii) roller mills, and (iii) very fine grinding mills which include (a) high speed pulverizing or hammer mill, (b) vibrating mill, (c) pin mill, (d) turbo mill, (e) fluid energy mill, (f) stirred media mill.

The design simplicity makes the Rocklabs Hammer Mill suitable for processing a wide variety of materials. It is particularly designed to process samples with high moisture content or those that tend to form lumps such as coal, limestone, laterite, saprolite, bauxite, and gypsum but can process all other rock types.

Hammer mill or Hammermill crushers are developed for both dry and wet crushing of brittle, mediumhard materials for the mining, cement, coal, metallurgic, construction material, road building, and petroleum chemical industries. Hammer mill or Hammermill crushers are impact type crushers and . Continue reading →

Description and principle of operation of the Hammer mill machine:The assembly and hammer arrangement of the hammermill machine is shown in appendix. The hammermill machines consist of the following components namely. Structural base. Bottom casing. Top casing (Hammer casing) Rotary discs. Transmission shaft. Hammers. Disc separators. Hammer hangers